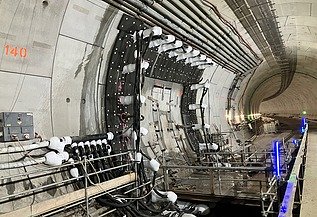

STRABAG is synonymous with the tunnel construction industry, consistently developing and investing in new approaches, ensuring the highest level of quality during planning, construction, and completion.

We offer a range of comprehensive tunnelling solutions with in-house capability for all tunnelling techniques.

Tunnelling capabilities in the UK

STRABAG UK combines cutting-edge technology with extensive technical know-how to seamlessly transform ambitious tunnelling projects into reality.

Our world-leading tunnelling specialists deliver sophisticated, efficient tunnelling solutions to projects in both complex urban environments and rural areas, ensuring minimum impact on the surrounding environment and communities.