Client:

Riverlinks Construction Joint Venture for TfL

Location:

London, UK

Build time:

2023 - 2024

Silvertown Tunnel

On behalf of Riverlinx Construction Joint Venture, ZÜBLIN Ground Engineering completed the drilling and artificial ground freezing during the excavation of four of the seven cross passages that connect the twin tunnels beneath the River Thames in Silvertown, east London.

Cross passages are essential for emergency routes and utility corridors between tunnels. The construction of the Silvertown Tunnel cross passages posed a unique challenge, as several are located below the water table in an area of high groundwater pressure.

To address this, the ZÜBLIN Ground Engineering team used artificial ground freezing for the construction of some of the cross passages to stabilise the soil, as it was not possible to dewater the ground from the surface.

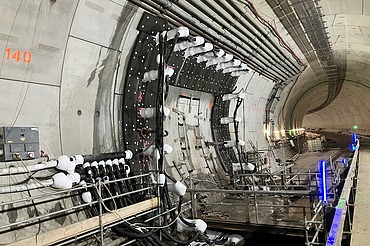

The ZÜBLIN Ground Engineering team initially used a small diameter rig to drill through the concrete tunnel lining before installing 26 steel freeze pipes, followed by the insertion of a plastic pipe inside them. The drilling and freezing works were undertaken from the southbound side of the tunnel, and the sections of the northbound tunnel cross-passage openings were then insulated to prevent any temperature loss.

A saline solution at -35°C was circulated in a closed-loop system through these pipes, gradually freezing the surrounding soil. Over approximately 55 days, the water-bearing sand layers were stabilised as a block of frozen ground formed around the pipes. This ensured that excavation could begin safely without the risk of any residual water ingress.

Two drainage pipes were installed to manage the groundwater pressure, and three temperature monitoring pipes equipped with sensors ensured the precise control and safe management of the freezing process. Two 200kW freeze units and two 100kW freeze units were in constant use during the freezing period.

The excavation of the cross passages began once the surrounding ground was completely frozen and stabilised. After excavation completion, the passages were lined with sprayed concrete and a waterproofing membrane. Finally, precast concrete segments were installed to reinforce and secure the structures.

Environmental and social responsibility

The artificial ground freezing technique was selected for its reliability and lower risk profile compared to other methods. As the freezing fluid is brine, it is environmentally friendly and safe for use within the surrounding environment.

Installation of the freeze pipes required minimal soil excavation, achieved with precise drilling, and the system was rigorously pressure-tested before use to eliminate any risk of leaks.

The entire operation was carefully designed to minimise disruption. The drilling and freezing process was vibration-free, with noise from the compact drilling rig kept to a minimum. Additionally, noise-insulated chiller units ensured the freezing phase remained as quiet as possible, making the entire project a low-noise activity.